- LED Light Sheet

- LED Strip

- LED Tape Light

- Edge lit LED Rigid Bar

- Backlit LED Rigid Bar

- Rigid LED Strip

- Neon LED Strip

- COB LED Strip

- Lighting Fixture

- LED Light Boxes

- Signage

- Signs & Retail Displays

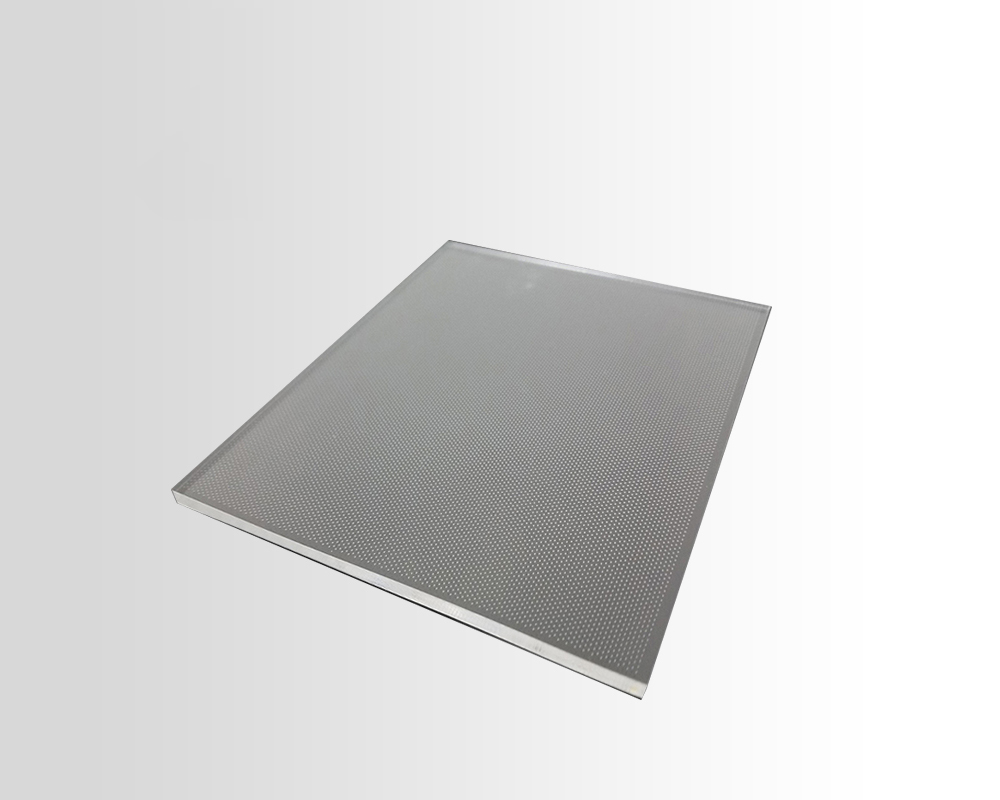

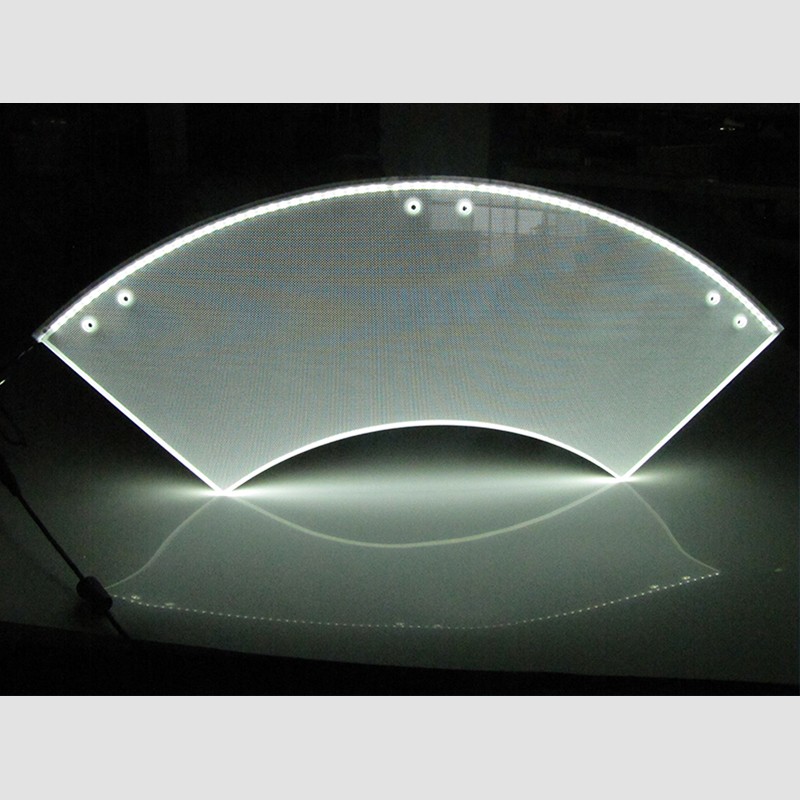

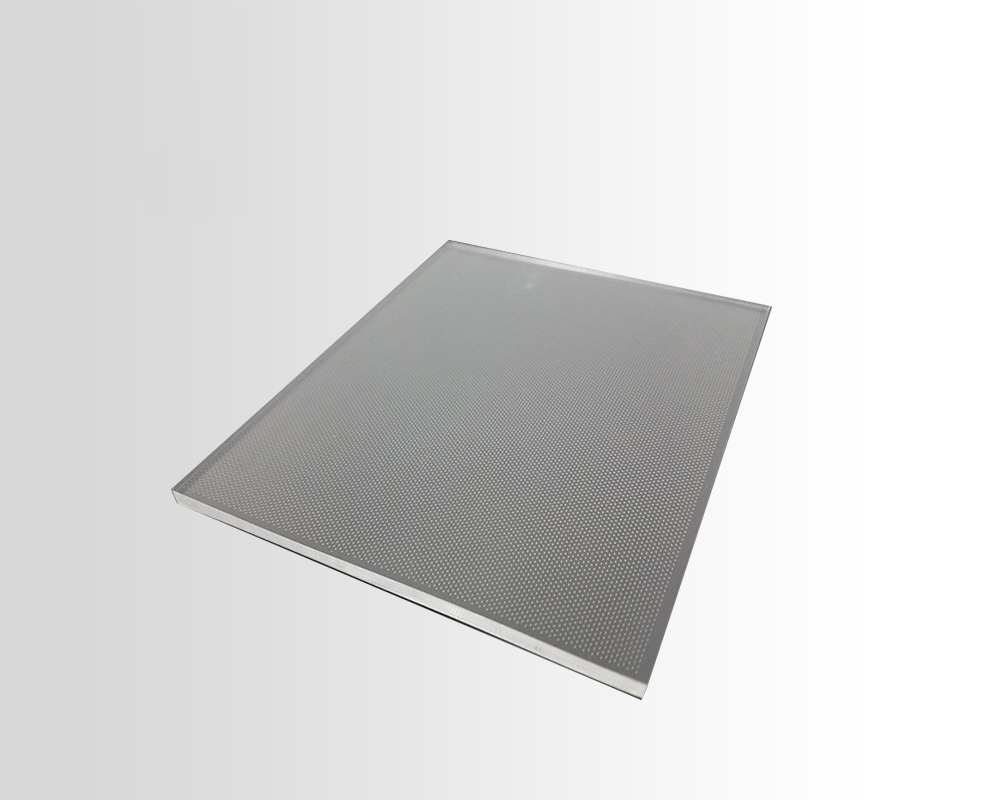

Laser dotting LGP

Laser dotting LGP is using pure PMMA optical grade acrylic as base material and adopting the most advanced 3D laser processing to create outstanding light uniformity with LEDs installed on it edge(s).INQUIRE+- DESCRIPTION

- TEMPLATE

- PACKING DETAILS

- DOWNLOAD

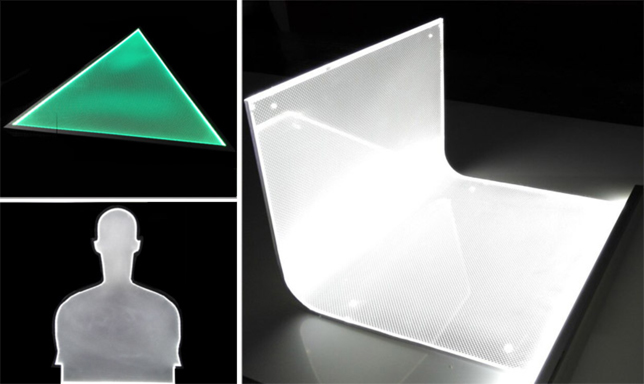

Laser dotting LGP for backlit

Laser dotting LGP is using pure PMMA optical grade acrylic as base material and adopting the most advanced 3D laser processing to create outstanding light uniformity with LEDs installed on it edge(s).

Laser dotting VS V cutting LGP technology

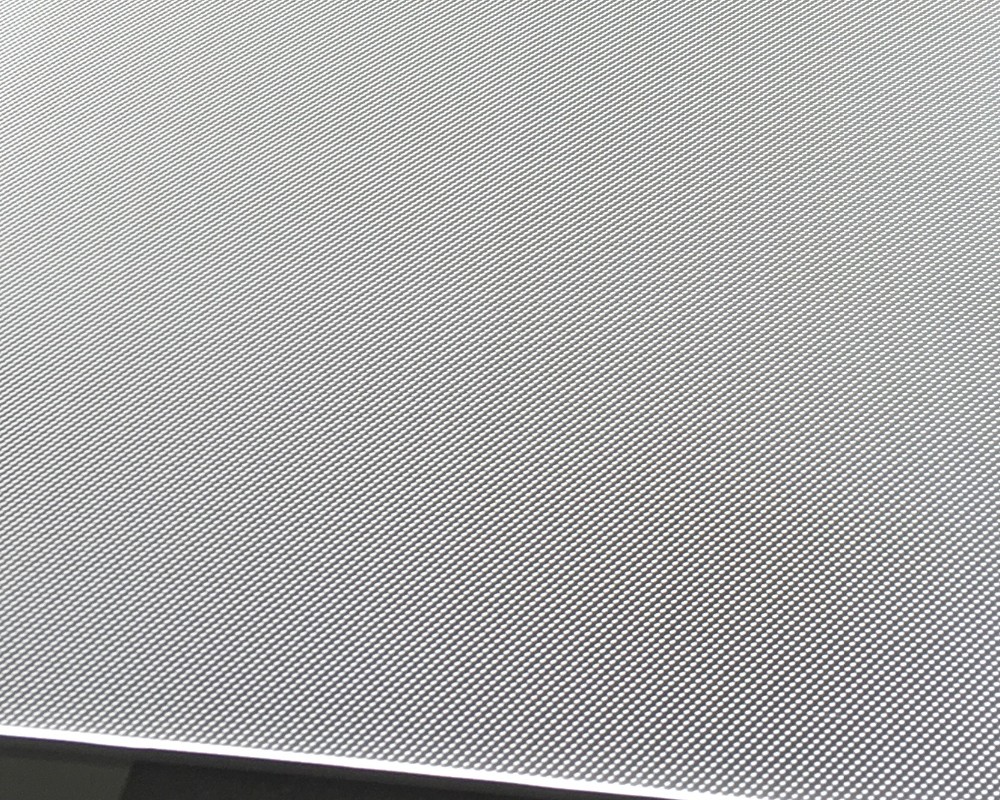

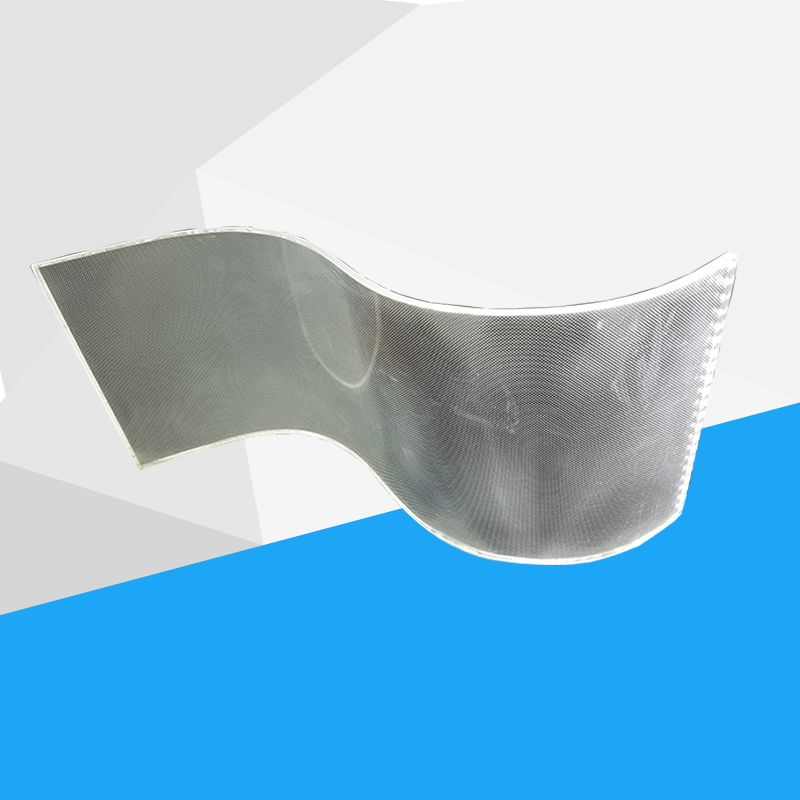

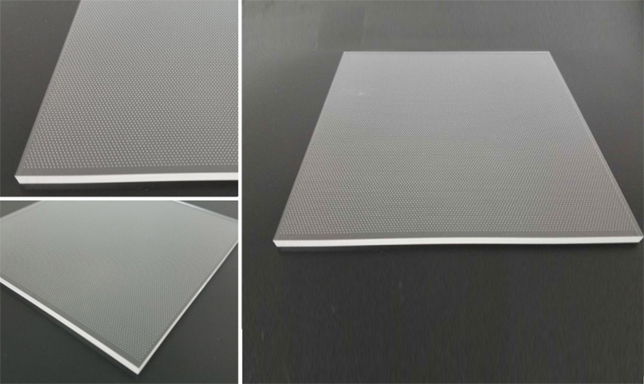

Laser dotting LGP is using the most advanced LGP technology of laser dotting to create better light performance than V cutting technology with latest advanced laser dotting machine, which is also higher efficency than CNC V cutting processing. Laser dotting technology can achieve more soft and even light even on thinner acrylic material.

Details:

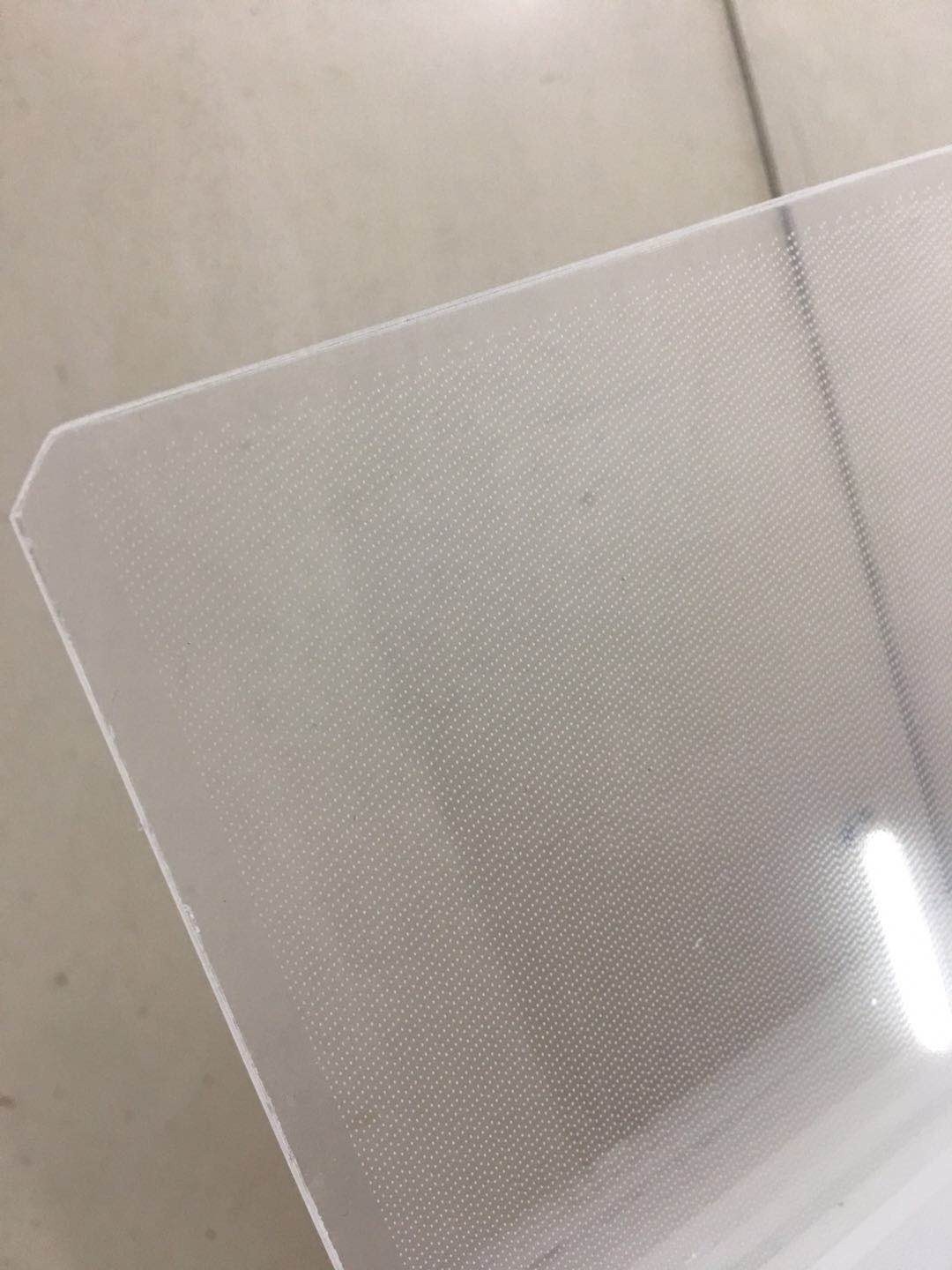

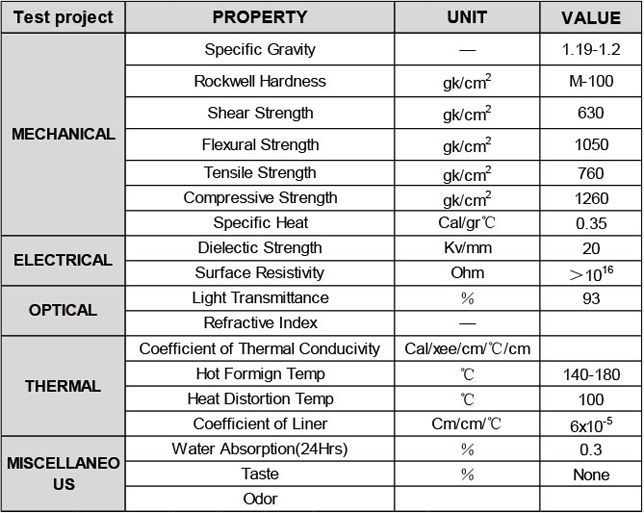

LGP(Light Guide Plate) is a transparent acrylic panel made from 100% Virgin PMMA resin, on whose bottom face a dot matrix is printed or a line matrix is scratched. The light source is installed on its edge(s). It makes the light coming from the light source evenly over the whole upper face of the acrylic sheet.

It uses pure PMMA optical grade acrylic as base material, using the most high-end technology 3D laser processing and engraving processing, the use of side light source in the cable or dot formed between the refraction, reflection and diffuse reflection light effects convert the line light source or point light source into the high-tech products of flat light source principle.

The light is soft and even with laser dotting LGP lite.

Net weight (kg) ≈ SQM (m2) * Thickness (mm) *1.2

- LED Strip